Frank told me that he’d bought me a surprise (of course, the give-away post title has already spoiled it for you!).

I walked into the kitchen after work to find this.

It didn’t work.

There are no maker’s marks on the unit; no lable to indicate which of the brands this is.

There was a velvet record cleaner in the case with the ‘His Master’s Voice’ logo on it, and a case for needles with “Brunswick” written on the lid.

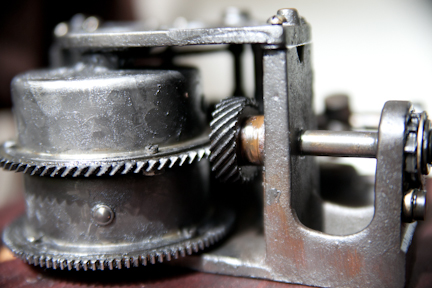

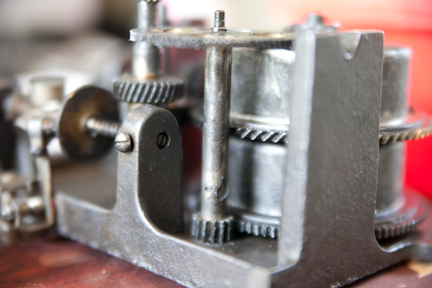

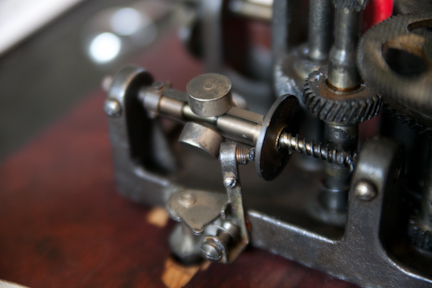

Frank and I, people that we are, dove inside to take a look at the mechanics and work out why it wasn’t working.

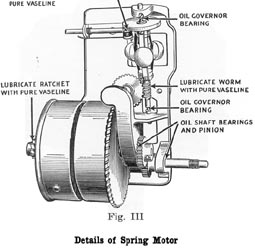

It is powered by a hand-crank dual-spring OKEH motor. (Yes, it is pronounced “okay”, but is in actuality the initials for Otto K. E. Heinemann (1877–1965), a German-American manager for the U.S. branch of German-owned Odeon Records.)

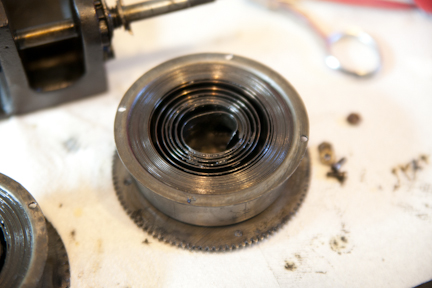

I took off the top of the cast housing, at which point the springs released fully (severely gouging the table I was working at, as the teeth of the cogs dug in – I guess just because it’s siezed doesn’t mean that there’s not pent up energy inside! Could have been rather tragic if my fingers had been in the way).

Now, I find myself with the task of reattaching the spring to the anchor on the arbor.

I did fully disassemble the housings last night, but couldn’t get the spring to hold.

I’m guessing that the hole became disfigured when the spring flew off, so I’ll have to use pliers to get it back on.

Seeing as I’m going to have to reopen the housings, I figure that I might as well give it a thorough cleaning.

The mechanism can be cleaned with Paint Thinner, I read, and then either grease / wheel bearing lube can be used to recoat everything, or a homemade vaseline:graphite (2:1) slop can be made.

I think I’ll go with the first option.

To describe how it works:

When you turn the crank, it turns a cog that rotates the top spring housing.

There is a ‘pin’ (arbor) that runs between the top and bottom spring housings which is connected to the spring through an anchor of sorts.

In order for the top spring to tighten as the crank is being turned, the arbor must remain stationary.

If the arbor moves with the top spring housing, the spring will never tighten.

The only way for the arbor to remain stationery is if the bottom spring is turning in the opposing direction with an equal force.

When sufficient potential energy has built up, the energy will transfer to the driving gear, turning the turntable spindle.

Well, that’s how I imagined it working anyway based on my ‘appraisal’.

The Disassembly

I took photographs along the way, to ensure that I’d put it back together correctly!

The Cleaning

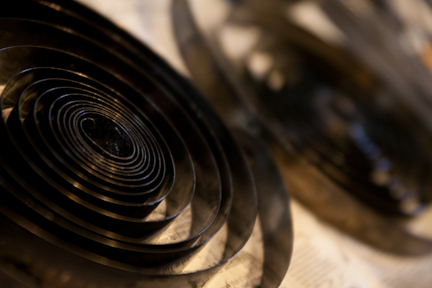

Lots of WD40, lots of paper towels, lots of elbow grease.

But in the end, the clean coils were generously coated with synthetic grease, and will hopefully last for another 110 yrs.

I was turning the coils directly into the housing, which took a LOT of strength and downwards pressure to stop everything from flying out.

Unfortunately, I noticed that bits of newspaper (my worksurface) were making their way into the base of the housing – not good – and all it took was that one moment of lapsed concentration, and the coil flew, slicing my left thumb and right thumb knuckle.

Frank heard the ‘snap’ as the coil released, and rushed in for fear that I might have sliced my juggular!!!

He wound the coils for me (wearing gloves).

The Injuiry

Why you should wear gloves 🙂

A video showing the directional rotations of the spring housings while charging.

As the machine was cranked, once fully reassembled, it was easy to feel that the potential energy was building within the springs, however as it reached its peak point, you could hear a dull thud as the the spring released from the arbor anchor.

One of them obviously wasn’t on quite all the way.

I disassembled the motor one again, after observing the spring housings while turning the crank.

The bottom housing was completely stationary, and as the top housing would turn, the arbor would turn too.

If the bottom housing were catching the housing, it’d have been totally stationary, but both housings would move.

I opened the bottom housing and tried three times to tighten the center-most coil so that it’d hold.

Finally, we had a winner.